Model

Maximum Capacity

- Features

◆ Maintains material integrity: The defoaming process does not alter material properties.

◆ Efficient defoaming: Provides clean, thorough and consistent defoaming.

◆ Optimizes material filling process: Reduces the difficulty of the filling process and ensures accurate filling.

◆ Prevents oxidation: Removes oxygen, preserving the quality and flavour of ingredients.

◆ Reduces wastage: Reduces wastage of raw materials and ensures process economy.

◆ Efficient and easy to clean: Easy to operate and clean, simple cleaning process.

◆ Automation: Various automation settings ensure easy operation with minimal setup.

◆ Enables continuous production requirements.

◆ Easy to maintain: Easy to maintain, minimizing downtime.

◆ Compact and space-saving: energy efficient for limited space.

◆ Handling of highly viscous materials: Easy degassing of highly viscous materials.

◆ Saves energy and space: No additional storage required, saves energy and space.

- Optional function

- Working Principle

For use with cooling circulation systems ■With □without □Customer provided

· Standard: AC380V±5%;3-Phase;50~60Hz

· Compliance with local grid conditions is available

Item

GM-iL-20HV

Working principle

VTR (Vacuum, Thin - film, Revolution)

Processing capacity

50 ~ 2000L/h(The processing capacity depends on the viscosity of the material)

Rotational speed

200~2400rpm, Accuracy 1rpm

Operation time

1~999h99m99sec ,Accuracy: 1sec

Program storage capacity

20 sets

Vacuum level

6mbar~1atm

Vacuum Capacity

Vacuum speed 300 ³/h

Vacuum source

■With □without □Customer provided

Vacuum setting

Independent vacuum on/off control, incorporated with vacuum delay function and allowing for arbitrary vacuum adjustment

Spindle gearbox temperature control

Cooling circulation system for temperature control of central spindle gearboxes

Chiller

Control software

7” touch screen panel, English interface

Remote communication

Remote communication based on SIMENS protocol

Safety measures

Vacuum sensors; gearbox oil level sensors; material overflow level sensors; regular maintenance and servicing; feed valve fault alarms.

Safety protection

Early warning in case of minor malfunction (spindle gearbox oil level/spindle temperature/vacuum/transmission abnormality)Automatic shutdown in case of serious failure(Vacuum seal cover abnormality/temperature overrun)

Ambient temperature and humidity

10~40 ℃ 、 20~80%RH

Voltage

Power

9.0KW;16A;50~60Hz,3-phase AC

Diameter of the cold - water pipe for chiller

DN15Φ20mm

Vacuum interface

KF40/Φ25mm/DN25

Feed Inlet and Product outlet flexible hoses

ODΦ20mm

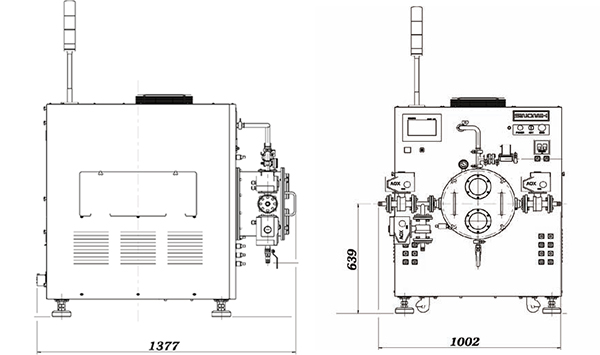

Dimension

958mm×1376mm×1356mm(1886mm)

Main machine weight

≈520Kg

- Dimensions