Application of Planetary Gravity Vacuum Defoaming Mixer without Blades in Composites

In the field of high-end composite material manufacturing, bubble residues and uneven mixing have long been key challenges limiting material performance. Traditional mixing equipment, due to issues like blade shear damage and low defoaming efficiency, struggles to meet the demand for high-precision materials in aerospace, new energy, and other fields. The emergence of planetary blade-free vacuum defoaming mixers, through three technological breakthroughs - 3D mixing + vacuum defoaming + non-destructive design - has brought revolutionary solutions to composite material preparation.

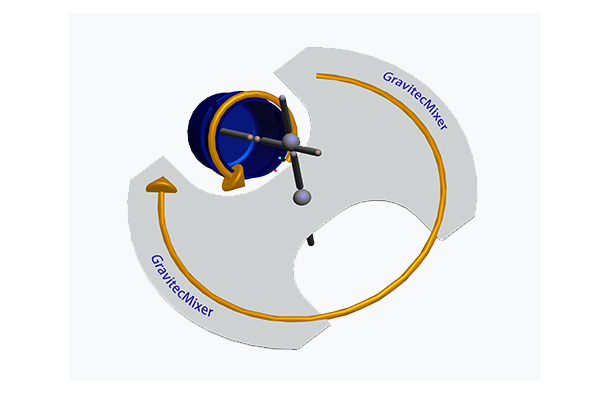

Technical principle:

- ✔️ 3D mixing eliminates dead zones

- ✔️ Fiber breakage rate <3%

- ✔️ Vacuum degree reaches -0.095 MPa

application

Aerospace

In the preparation of carbon fiber prepreg for key components such as aircraft wing beams and satellite brackets, the equipment achieves breakthroughs through the following innovations:

- Gradient Vacuum Technology: Adjusts vacuum degree in stages (-0.08 → -0.095 MPa) to prevent premature resin gelation

- Fiber Orientation Control: The centrifugal field generated by planetary motion keeps fiber orientation deviation below 5°

Case Study: 12% weight reduction and 40% fatigue life improvement in a drone main wing

Electronic Packaging

For nano-silver paste preparation in 5G chip packaging, the equipment demonstrates unique advantages:

- Submicron Dispersion: Silver particle (D50=0.8μm) agglomeration rate reduced below 3%

- Low-oxygen Environment Mixing: Oxygen content in vacuum chamber below 50ppm, preventing silver oxidation

| Performance Indicator | Traditional Process | Our Equipment |

|---|---|---|

| Thermal Conductivity | 8 W/mK | 12 W/mK |

| Bonding Strength | 15 MPa | 22 MPa |

New Energy Batteries

Key technological breakthroughs in silicon-carbon anode slurry preparation:

- 3D Conductive Network Construction: Carbon nanotube (CNT) distribution uniformity CV value below 8%

- High Solid Content Mixing: Viscosity stability ±5% at 72% solid content

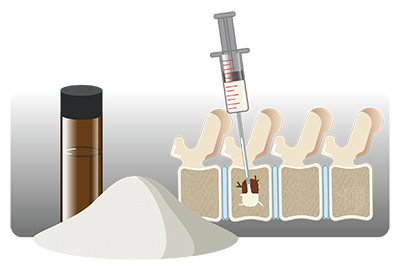

Biomedical

Biomedical engineering applications in biodegradable bone cement preparation:

- Microporous Structure Control: Pore diameter 50-200μm accounts for over 80%

- Drug Sustained-release Integration: Gentamicin loading rate over 95%, burst release rate below 5%

Clinical Tests: 30% reduction in bone healing cycle, postoperative infection rate decreased to 0.8%

Performance Comparison

| Indicator | Traditional Equipment | Our Equipment |

|---|---|---|

| Mixing Uniformity | 85-90% | ≥99% |

| Bubble Residual Rate | 0.5-1% | <0.1% |

| Fiber Damage Rate | 10-15% | <3% |